|

Prototype Parts

Once the design is worked out, it is time to

have a prototype part or assembly built. A prototype

part can tell you many things before money and time are committed to tooling:

- How does the part feel - is it too heavy, not heavy enough

- Does the part feel right in your hand, or is it stable in use?

- Do the parts fit together as expected - do all the screw holes line up?

- Can the parts be assembled in a sequence that doesn't cause issues?

- Are there unexpected tolerance issues?

- Does the product actually work - does it function as expected?

- Do your customers like it? Do marketing and sales like it?

Prototypes have other uses: trade

shows and publication photos. Many times the time line for a

product is based on an upcoming trade show or trip to a potential

customer's facility. There may not be sufficient time to tool

up for production runs, but there are numerous ways to build

prototypes in less time.

|

|

|

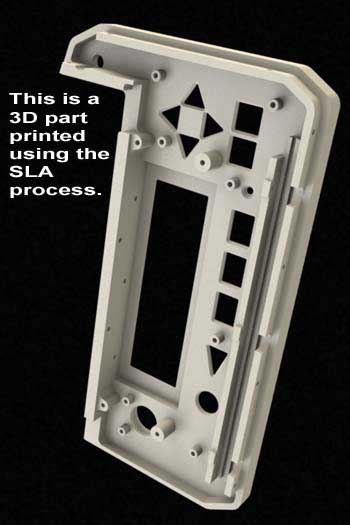

Prototyping Injection Molded Parts:

Rapid Prototyping, also called 3D printing

or Additive Manufacturing, has been around for a while, but has

grown in popularity in the last several years. Once a

CAD model has been created and approved, the file is output in STL

format, the format used by most 3D printers.

3D printing comes in several flavors, depending on the accuracy needed and on what

you will use the prototype for;

- SLA - Stereo lithography. The

most common technique when just one or a few parts are needed. Good

for parts with fine detailing. Presentation

Models. Can be used for casting or molding

patterns. Form and fit testing can be done.

- SLS - Selective Laser Sintering.

Produces tough parts that are good for form and fit testing of

designs. Can be used to produce low volume production

parts. Good detail and surface finish.

Dimensionally accurate with thousandths of an inch.

- FDM - Fused Deposition Modeling. Very

rugged parts that can be used for fit, form and function

testing. Are almost as strong as the final, injection molded,

parts. Good for parts that have threaded inserts, or

that will require additional machining.

- DLP - Digital Light Processing

- PJET - Polyjet A proprietary method

which can be used to print multiple materials on the same part, for

example to simulate an over molding process.

- ZCorp - Z Corp 3D Printing

|

| |

|

Sheet Metal Prototyping:

Higher volume sheet metal parts are often stamped

using CNC turret punches, which sometimes require custom punch and die sets. Even larger

volumes might be hard tooled, an expensive and time consuming process.

To prove out a design, or make a deadline, prototype sheet metal parts can be laser cut,

or even water jet cut. In fact, some production parts are ideally suited for these processes,

neither of which require special tooling. Most precision sheet metal vendors

have lasers and can provide this service.

Water jet cutting is not as common, but available if needed. It is ideal for cutting

copper, silver and other materials that are not suited for laser cutting.

|

|